ErmaFlex

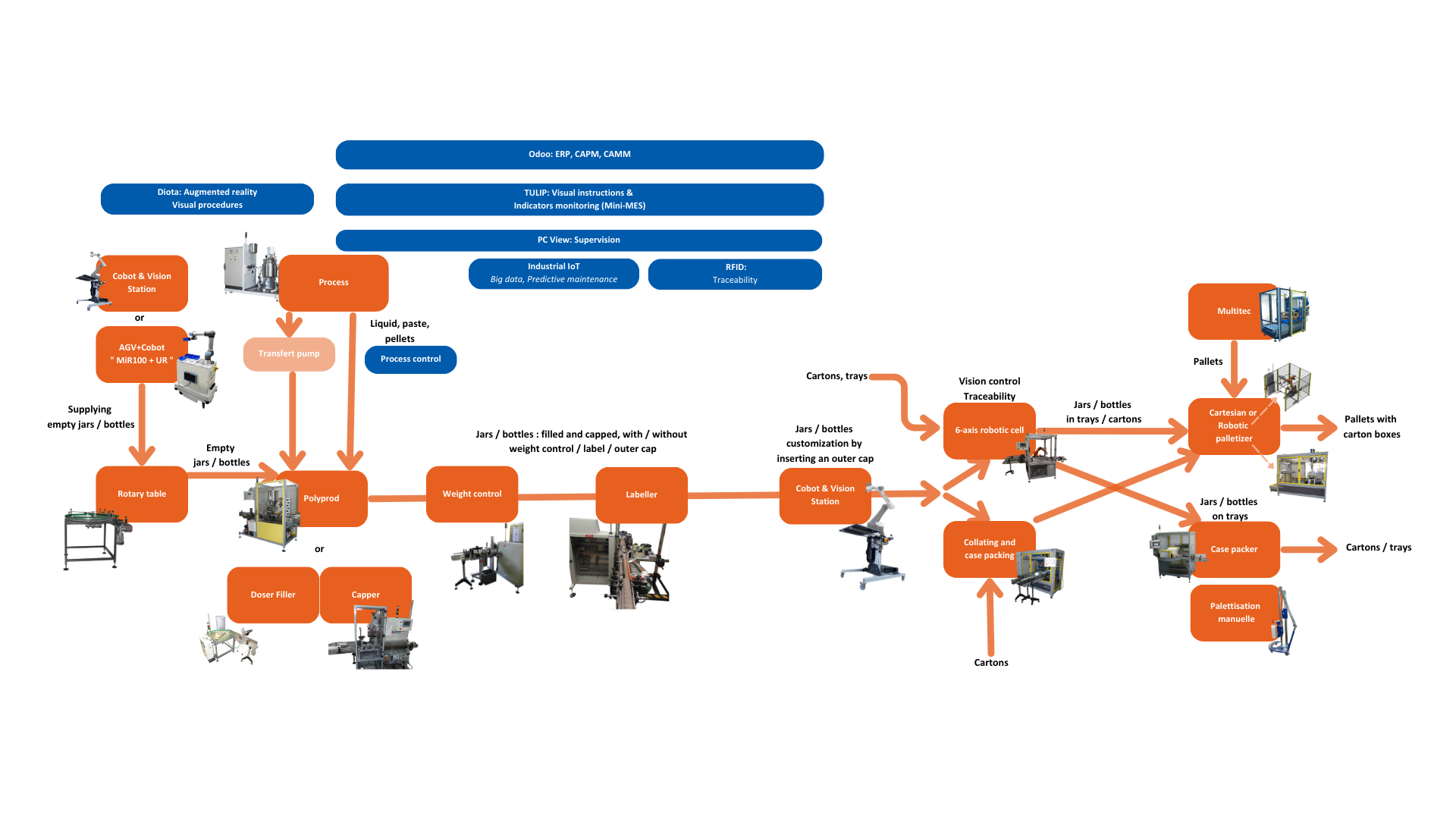

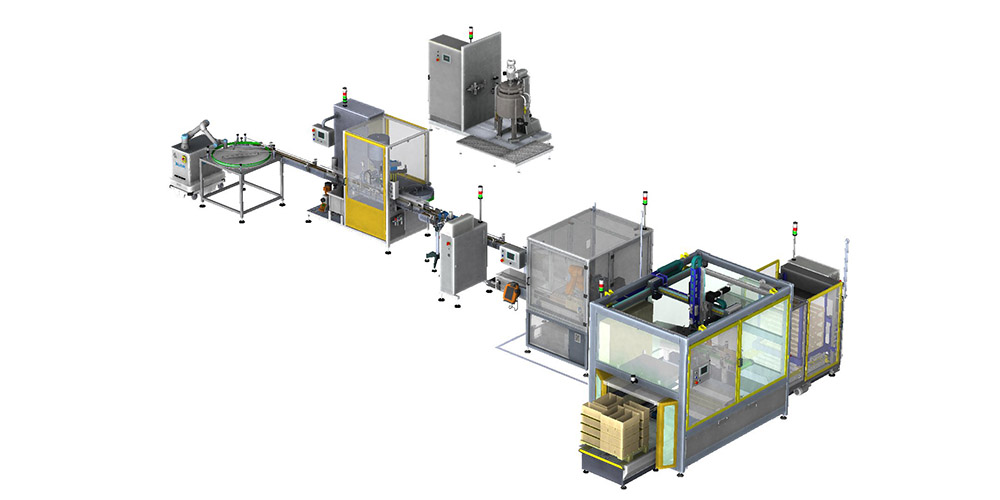

Automated production, packaging and palletizing line, multi-product and multi-format

Presentation

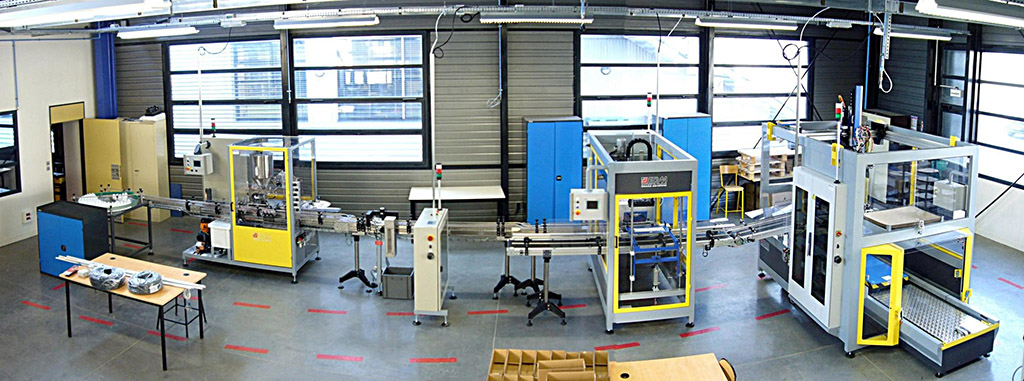

ErmaFlex is an educational production line made up of stand-alone, modular systems that can operate separately. Customers are free to build their own line to suit their needs and budget. The systems are accompanied by numerous sub-systems to increase the number of workstations. ErmaFlex brings electrical, pneumatic, hydraulic and mechanical technologies to the fore. It can be used to teach production control and production management, industrial maintenance, automation and robotics.

"Industry 4.0" themes covered

Technical solutions

🔹PLC, Siemens and Schneider HMI & Supervision

🔸 Visual instructions & MES Tulip

🔹 IO-Link Smart sensors & Industrial IoT gateway

🔸KUKA industrial robot

🔹 Universal Robots or Omron or Dobot collaborative robot

🔸Cartesian robot

🔹Sick light curtains

🔸Diota augmented reality

🔹Virtual reality Virtual Indus

🔸Virtual Universe Pro 3D digital twin

Key points

Quick preparation

Easy preparation of activities thanks to instant start-up

Easy to clean

Operation with recyclable consumables (pellets, water) and no cleaning before and after use

Multi-product use

Multi-product use (pellets, liquid, semi-pasty) and multi-formats (jars, bottles, cartons, trays)

Reliable equipment

Reliable equipment (welded frame and industrial components) allowing many assemblies, disassemblies and format changes

Upgradeable line

Upgradeable line (integration of peripheral systems and parts) and consumables (dimensions of jars, bottles...) according to the budgets

Teaching activities

• Production

• Line operation

• Line reconditioning following a change

in production format

• Supervision on Ethernet network)

• Action and acquisition chains

• Regulation and control

• Diagnosis

• Prevention

• Improvements

• Assembly and disassembly

• Adjustments

• Wiring and connection

• Scheduling

• Control charts

• Lean SixSigma

• Automation

• Robotics

• 3D constructive solutions

• Workstation extensions

Our partners and suppliers