Our systems ErmaFlex

Find out more about all the systems in the ErmaFlex didactic line

#0: Process

The Ermaflex Process is an automated system for manufacturing liquid, pasty and semi-pasty products

- Schneider M340 PLC & HMI Siemens KTP700

- Triple-walled stainless steel tank with controlled heaters, mixers and water cooling

- Mixer and propeller

- Manual hydraulic lifting system to open the cover

- Quick tank cleaning by rotary spray head

- Production of several recipes (shower gel, detergent, etc.) and possibility of creating your own recipes

- System similar to those used in pharmaceutical,

cosmetics and food industries

#1: Rotary table

Dispensing table to feed the conveyor of the Polyprod or the Doser

with empty jars / bottles.

Empty containers can be supplied either manually by an operator, by a

Cobot & Vision Station, or by an AGV + Cobot ‘’MiR100 + UR’’

#2: Polyprod

Polyprod is a filling and capping machine for liquids / pastes / pelltes in jars / bottles

- Schneider M340 PLC & Siemens KTP700 Touch Panel

- ASi communication bus towards sensors and valves

- Volumetric dosing (diaphragm pump) for liquids

- Worm gear dispenser for pellets

- Pneumatic gripping / screwing head (cylinder and motor)

- Reed switch, inductive, photoelectric, capacitive and optical fiber sensors

- Wide variety of technologies and activities possible in production and maintenance management

- Many options for maintenance activities

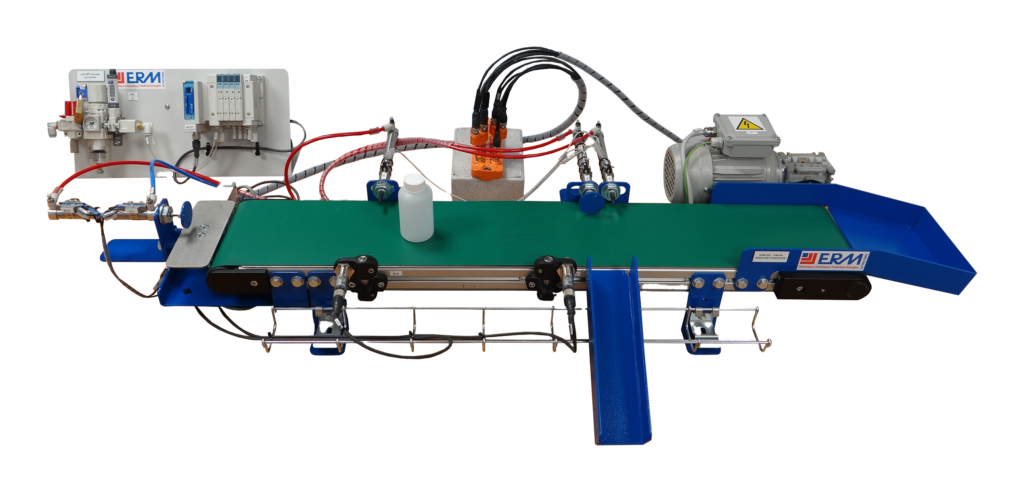

#3: Doser-Filler

Dosing and filling of liquids / pastes / pellets in jars / bottles

- S7-1200 PLC & KTP700 HMI (Siemens)

- Volumetric dosing pump

- Conveyor with pneumatic positioning

cylinders

#4: Capper with mechanical cams

Synchronized operations of placing and screwing caps on jars / bottles

- S7-1200 PLC & KTP700 HMI (Siemens)

- Set of two cams controlling the vertical motion of the screwing head and the rotation of the cap placing device

- Pneumatic motor, cylinders and vaccum cup

- IO-Link smart sensors

Mechanical system for high-speed operations with advanced mechanical adjustments

#5: Weight control

Weight control of packaged jars / bottles with ejection of the non-compliant ones

- S7-1200 PLC & KTP700 HMI (Siemens)

- Siemens weighing system

On-line quality control and production statistics

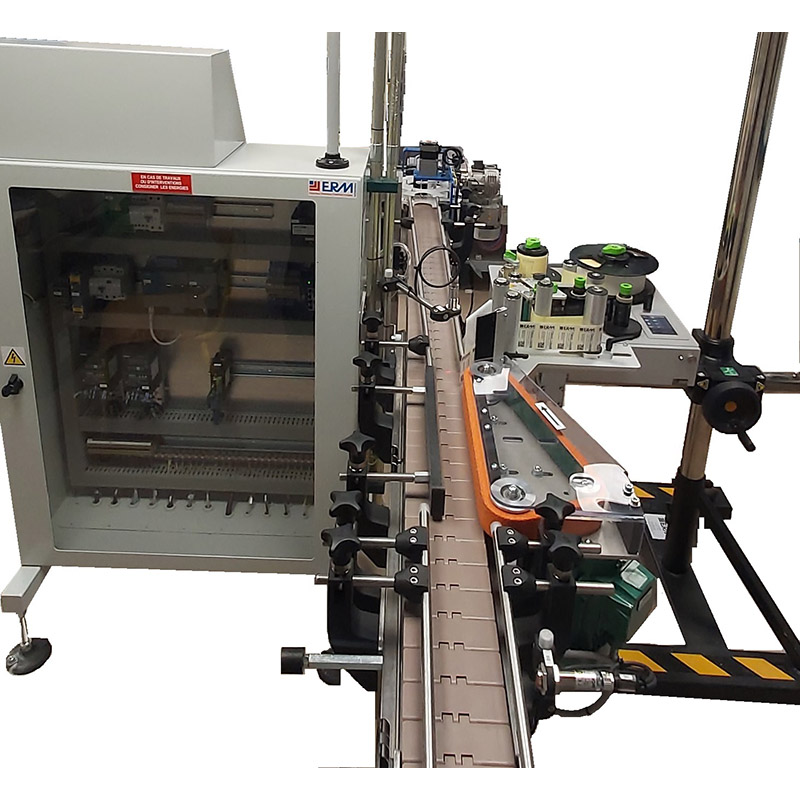

#6: Labeller

Printing and placing self-adhesive labels on jars / bottles

- Label format can be set from the Weight control HMI

- Feedback of status information and monitoring on the Weight

control workstation and supervision - Label creation and configuration software included

#7: Cobot & Vision station Dobot/Omron/UR

Implementation of a 6-axis collaborative robot with vision

- Customization of jars / bottles by placing an overcap

- Flexibility in production

- Learning about collaborative robotics

- Safety laser scanner, SafeSkin wearable accessory (Option)

- 2D camera (Option)

- Collaborative grippers (Option)

Download the technical data sheet Omron

#8: Collating and case packing

Packing jars / bottles into cartons

- Schneider M340 PLC & Siemens KTP700 HMI

- YZ 2-axis transfer system

- Vacuum and gripper heads

- Sensors (optical fibre, reed switch, photo-electric,

incremental encoder)

With :

– 2 types of containers

– 2 gripping heads

– 2 types of carton boxes

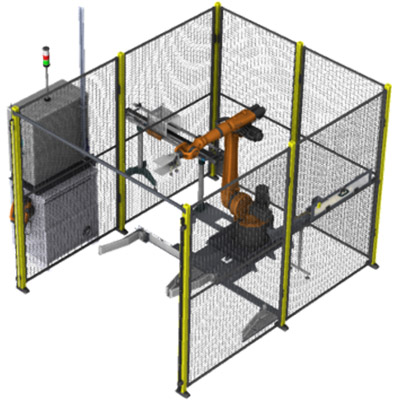

#9: 6-axis robotic cell with vision control and RFID

Packaging cell for jars / bottles in cartons / trays with KUKA

robot

- S7-1200 PLC & KTP700 HMI (Siemens)

- 6-axis industrial robot (Kuka Agilus with 700mm reach, 6kg payload) with Profinet communication

- Vaccum and gripper heads

- IO-Link smart sensors

- Vision sensor for in-line quality control

(screwing) - RFID transceiver (traceability)

- KUKA Connect predictive maintenance

- KukaSim, 3D simulation software from Kuka

- Complete industrial packaging training system (packing, quality control and traceability)

- Strong partnership between Kuka and ERM in education: Organization of training sessions (2 modules offered)

#10: Case packer

Packing of trays into carton boxes

- S7-1200 PLC & KTP700 HMI (Siemens)

- Pneumatic cylinders and distributors

- Rotary table with indexing cylinder and safety sensor

- Format change (cartons / trays)

- More wiring workstation with the cabinet’s

removable plates

#11: Cartesian palletizer

Stacking cartons / trays on pallets

- Schneider M340 PLC & Schneider HMI

- XYZ 3-axis transfer system with brushless motors

- Vacuum or gripper heads

- Hydraulic lifting table

- Rotary/linear cylinders and vacuum cups

- Sensors (reed switch, photo-electric, inductive, potentiometric, incremental encoders)

- Light barrier

- 3 different technologies in a single system

(electric, pneumatic, hydraulic) - Automatic tool change (for inserting a separator)

#12: Robotic palletizer

Carton/tray palletising cell designed around a KUKA robot

- S7-1200 PLC & KTP700 Touch Panel (Siemens)

- 6-axis industrial robot (Kuka Cybertech with radius 2010 mm, load 16 kg) with Profinet communication card

- Gripper and suction cup heads

- IO-Link intelligent sensors

- Light barrier

- KUKA Connect predictive maintenance

- KukaSim, 3D simulation software from Kuka

- Strong partnership between Kuka and ERM in education

# 13: Multitec

Stacking and unstacking of pallets

- PLC & HMI (Siemens or Schneider)

- Electric, pneumatic or hydraulic vertical axis

- Roller conveyor

- Pneumatic cleats for the pallets gripping

- Sensors (reed switch, linear position)

- 3 different technologies in a single system (Electric, Pneumatic, Hydraulic motion)

- Motion kits not mounted on the Vertical Axis unit may be used for training activities

Other Solutions

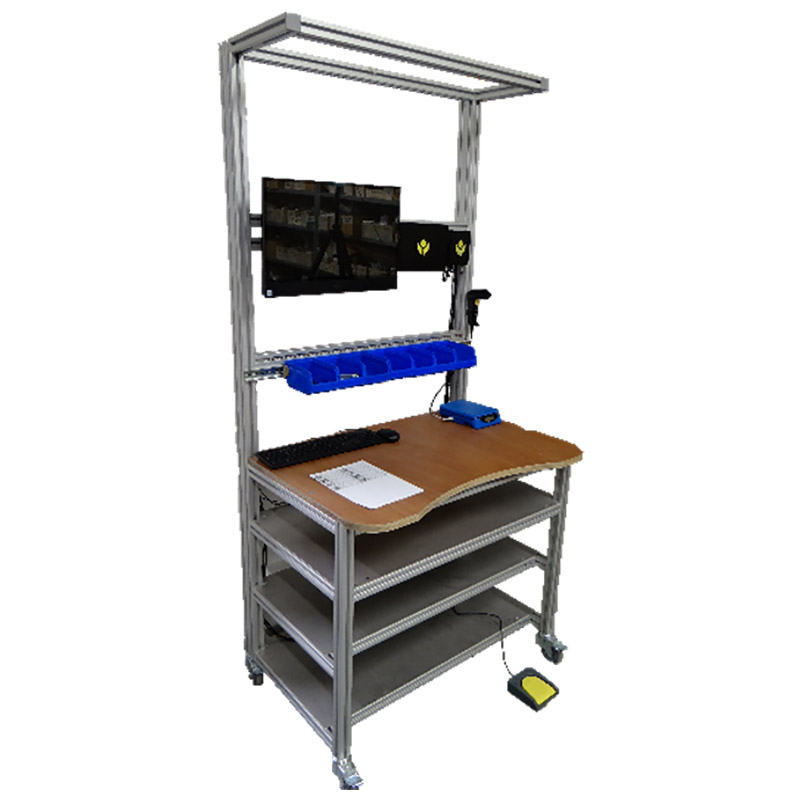

#C: Connected workstation for assembly, quality control and sampling

Manual workstation connected with IoT devices for product assembly, quality control and sampling of the various products of both ErmaSmart and Ermaflex lines

- Ergonomic workstation with touchscreen and integrated PC

- IoT Tulip Edge I/O Gateway

- Tulip software for visual instructions & production indicators monitoring

- Tulip Light Kit (Pick-to-Light) to guide the operator on which parts to use according to the current assembly stage

- IIoT Lean tools (barcode scanner, pedal, Andon beacon, break beam sensor)

- Connected scales, calipers and screwdrivers

#D: Order preparation & Manual palletizing station

Preparation of customer orders:

- Ensuring RFID control / traceability of cartons and/or pallets

- Placing and organizing cartons and operating the pallet stretch wrapping machine

- Collecting information for shipping and traceability

- RFID tags for cartons and/or pallets

- Manual stretch wrapping machine

- Integration with ERP/CAM/MES environment

Digital tools 4.0

Digital Chain

» CMMS Capilog

Capilog is a complete CMMS software package with PC, tablet and smartphone interfaces.

Capilog offers the following intuitive functional coverage:

- Task management and planning

- Management of preventive maintenance, operating procedures and preventive maintenance by type

- Equipment management

- Stock management

Academic version without subscription or updates.

Tulip «

Tulip is a web-based environment for creating digital applications on tablets and touch screens.

- 0-paper visual intervention procedures on the ErmaFlex line

Machine supervision via OPC-UA to retrieve production data - Declarations of production stoppages and faults

- Continuous improvement suggestions from operators

- 0-paper control using connected tools (scales, etc.)

- Dashboards for monitoring production indicators (OEE, throughput, etc.)

- Easy modification of applications and creation of new ones (100% graphical)

- Implementation of lean manufacturing concepts (Andon, 5S, etc.)

» Supervision PC Vue

Supervision WinCC Professional for remote control of the ErmaFlex line from synoptics.

– Recording of production rates and monitoring of breakdowns

– Recording of events occurring during production

Ease of use of WinCC Professionnal (Siemens TIA Portal environment) for in-house developments

Odoo «

Odoo integrates all the company's functions, from quotations to delivery notes, including purchasing, stocks, etc.

As part of the ErmaFlex training line, ERM has integrated Odoo with Tulip to offer an integrated production company management solution:

- Quotations and order entry

- OF launch and planning

- Purchasing and stock management

- Production traceability

- Delivery notes

- Machine maintenance management…

Digital tools 4.0

Automation 4.0 & Industrial IoT

» Smart IoT Gateway Kits Sick TDCE & Smart Sensors

Study and implementation of an IoT monitoring and alert system

- IOT gateway and several intelligent IO-Link sensors

- Indoor (with additional antennas) and outdoor localisation

- Transformation and contextualisation of sensor data via NODERED

- Setting up local surveillance screens via NODERED

- Setting up CLOUD surveillance screens (Option)

- Visual, e-mail and SMS alerts

- Communication: Wi-Fi, Ethernet (multi-protocol), serial links

- Scalable solution ideal for project activities

Smart IoT Sick Gateway Kit TDCE & Smart Sensors «

Study and implementation of maintenance alerts using the IOT

- Implementation of sensors in a case

- Use of intelligent sensors (with on-board tasks) and IO-Link

- 6 sensors and a conveyor to carry out 5 themes of curative, preventive or predictive maintenance

- Use of the NODERED tool to link data and create SMS and email alerts, etc.

- Local or remote Dashboard production using a CLOUD

» Industrial IoT IFM moneo & Smart Sensors

Study and implementation of an IoT monitoring and alert system

- IO-Link Master combined with an industrial PC running IFM’s Moneo IIoT software, including:

– Configure: parameterisation of sensors and IO-Link masters

– RTM: Creation of dashboards, analyses and alarms - IO-Link intelligent sensors

- Kits delivered with a detailed procedure facilitating implementation on systems by teaching teams and learners

- Scalable solution ideal for project activities

- Unrivalled environment for connecting multiple systems (e.g. production line)

Sensopart industrial vision case «

Industrial vision training

- Object detection, presence and assembly control, counting and measuring operations

- Used alone for vision activities, or embedded in an industrial system

- Many educational activities based on industrial vision

» Automate 4.0 environment

Evolving environment to put the factory of the future into practice

- Modular, scalable offering, from the PLC board to the mini-factory of the future

- Secure PLC enclosure with protection for professional wiring on

terminal blocks - Industrial solutions incorporating modern technologies:

– RFID IO-Link for traceability

– Pneumatic assembly incorporating IO-Link components

– Weighing (strain gauge)

– Vision (camera)

Digital tools 4.0

Twins & Digital Models

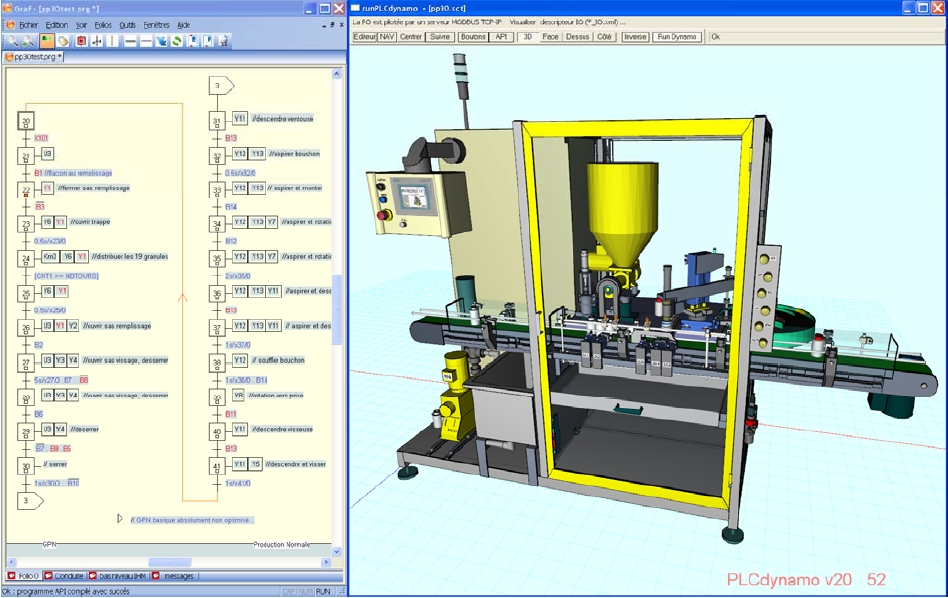

» ErmaFlex programmable 3D digital models

Digital twins of 6 ErmaFlex production line systems

- PLC programming (Grafcet and GEMMA via the integrated editor)

- System control with its Man/Machine Interface

- Maintenance diagnostics

Programmable digital mock-up on the following systems:

- Multitec (Pallet stacker/unstacker)

- Polyprod (Filling and capping machine)

- Weight Control

- Regrouping Case Packing

- Palletiser

- Process

Digital tools 4.0

Augmented Reality & Remote Assistance

Diota enables geometric data (3D models) and procedural data (instruction sheets, etc.) from industrial systems to be restored to operators in real time in order to improve complex human operations: Assembly, Operation & Maintenance, Quality Control & Conformance

- Augmented reality on tablet and PC, projective system and Hololens 2

- Markerless technology for superimposing virtual elements (3D models, tools, etc.) on the real thing

- Field data collection (photos, operations reports, etc.)

Can be interfaced with MES and supervision software, etc. - Integration with SolidWorks/Catia

- Composer or Diota Editor to graphically create augmented reality scenarios from the 3D model of the system

⇒ Teaching methods:

- Operator/technician level: Augmented reality-guided interventions and creations (scenarios available on various ERM teaching systems)

- Senior technician/engineer level: Creation of augmented reality projects and scenarios on SolidWorks/Catia Composer and Diota to assist operators and technicians.

Hololens 2 «

Mixed reality to support operations

Hololens 2 is a mixed reality headset from Microsoft. Combined with Microsoft Guides software, it provides assistance for production and maintenance operations:

- Development in Microsoft Guides of assistance procedures /routines on a machine

- Step-by-step monitoring of procedures/routines using the Hololens headset with mixed reality (real-time superimposition of texts, videos, documents, images, 3D objects, etc.)

Combined with Teams, Hololens 2 can also be used to provide remote assistance via streaming, using augmented reality tools.

» Epson Moverio Pro & Brochesia

Augmented reality for remote assistance

Epson Moverio is a true hands-free visual assistant

- Hands-free visual assistance in augmented reality with a remote streaming expert

- Features: Audio / Video streaming for two or more people, Photo capture, Video recording, Remote pointer, Annotation of images and screenshots, Real-time annotation, Transfer of documents from the Expert PC, Screen sharing, Chat…

- View video, photos, instructions in AR in the Epson glasses of the technician on site

Digital tools 4.0

Virtual Reality

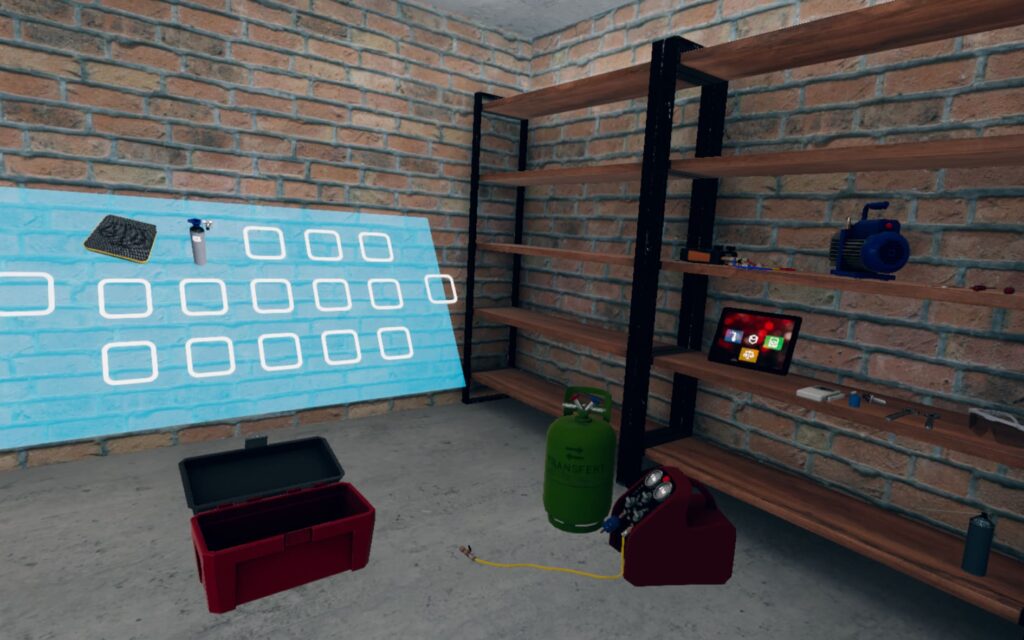

» Virtual Indus "Production management"

Learning procedures for managing automated industrial production systems

- SPC1 Statistical Production Control module

– Sequence 1a: sampling procedure, graphic representation and interpretation of results

– Sequence 1b: statistical control with control chart and production validation

– Sequence 1c: statistical control, identification of deviations and/or malfunctions and reactions - SPC2 Statistical Production Control module

– Sequence 2a : qualification of the dosing machine

– Sequence 2b: control by control card

» Virtual Indus "Electrical certification"

Learning safety procedures for electrical work

- B1V electrical accreditation: Carry out an electrical operation in a reinforced LV vicinity zone (zone 4) with the installation and removal of an insulating sheet.

- BS electrical accreditation (2 BAT & INDUS sequences): Carry out an elementary low-voltage operation on a de-energised installation element outside zone 4.

- BR electrical accreditation: Replace a faulty component after consignment on your own account and put the installation back into service requiring an adjustment task.

- B2/BC electrical authorisation: Carry out consignment in one stage, supervise work entrusted to subcontractors, carry out de-energised electrical operations in simple vicinity (zone 1) and deconsign at the end of the work.

» Virtual Indus "Maintenance & Diagnostic"

Learning industrial maintenance and fault diagnosis procedures

Electrical Diagnostics & Maintenance module with 3 types of random faults on the Polyprod, dosing and industrial capping system

Carrying out an activity:

- Troubleshooting on an immersed system

- Search for the cause of a fault on a technical file (electrical diagrams, etc.)

- Change the faulty component underwater

- Restart and test the system