Our systems Regulflex

Find out more about all the systems in the Regulflex didactic line

#1: Buffer tank

(flow level control)

Training workstation for level and flow control (tank at the beginning of soft drink production line)

- Level measurement (capacitive, hydrostatic)

- Flow measurements (rotary vanes, ultrasound)

- Valves (control valves with integrated electro-pneumatic positioner

and position feedback, solenoid delay valve) - Pumps (volumetric with rotary vanes, controlled by a variable speed

drive, with analog control and feedback) - Inverter (variable speed drive, current-to-voltage)

- Storage (atmospheric stainless steel tank)

- Communication & Fieldbus (Ethernet, Hart)

#2: Dosing

(flow & ration control on liquids)

Training workstation for flow and ration control (syrup dosing system in a soft drink manufacturing process)

- Level detection (ultrasonic)

- Flow measurements (rotameter, rotor)

- Other measurements (Brix degree, density)

- Valves (with integrated electro-pneumatic positioner and position

feedback) - Pumps (volumetric diaphragm dosing with analog and digital control)

- Storage (PVC tank)

- Communication & Fieldbus (Ethernet, Hart)

#3: In-line refrigeration

(temperature & flow control)

Training workstation for temperature and flow control (cooling unit in a soft drink manufacturing process)

- Flow measurements (vortex, thermal mass)

- Temperature measurements (PT100, PT1000 duplex sensors, J

thermocouple, K thermocouple, displays/transmitters,…) - Valves (with integrated electro-pneumatic positioner and back to

position) - Pumps (rotary vane pumps with variable speed drive, analog

control and feedback) - Converter (variable speed drive, voltage-to-current, current-tocurrent)

- Process components (plate heat exchangers, automatic air

valve) - Industrial refrigeration (condensing unit, pressure reducer, filter

drier, HP/LP pressure switches, etc.) - Communication & Fieldbus (Ethernet, Hart)

#4: Carbonation

(gas pressure & flow control)

Training workstation for flow and pressure control (carbonation system in a soft drink manufacture)

- Measurement of liquid products (temperature with PT100 probe, electromagnetic

flowmeter, relative pressure transmitter, etc.) - Other measurements (dissolved CO2)

- Valves (control valves with integrated electro-pneumatic positioner and back

to position, CO2 thermal mass controller and relative pressure controller) - Process components (static mixer, heater and gas regulator)

- Communication & Fieldbus (Ethernet, Hart)

#5: Pressure vessel

(pressure & level control)

Training station (pressurized tank) for pressure & level control at the end of a soft drinks production line

- Level measurement (capacitive probe)

- Pressure measurements (relative pressure transmitter)

- 2 solenoid control valves for gas intake and exhaust with

electric positioner - 3 on/off solenoid valves (liquid filling/draining, leakage)

- Storage (stainless steel pressurized tank)

- Communication & Fieldbus (Ethernet, Hart)

Control modules

Industrial process controller

Trainer for PID controller

- Process control (industrial controller)

- Dual-loop PID controller, independent or linked

- Communication (Ethernet, Modbus) & Supervision

- Settings on the front panel (P, TI, Td, SP,…), Auto/Manual switch,

measurement display and settings - Self-adjusting function for searching for P, I, D parameters

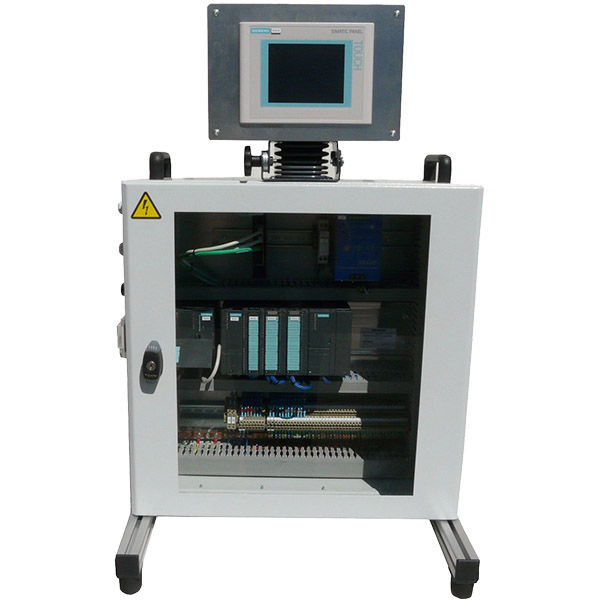

PLC trainer for PID control

PID control trainer with PLC

- Process control (PLC with PID function)

- HMI touchscreen

- Supervision on control loops

- Communication (Ethernet, Hart, Io-Link) &

Supervision - Programming by PC via Ethernet link

Distributed Control System

Trainer for Distributed Control System

- CProcess control and supervision (Digital DCS)

- Communication (Ethernet, Modbus, Profibus optional)

- High-sampling graphic function for drawing curves and

collecting data - Self-adjusting function for searching for P, I, D parameters