Presentation

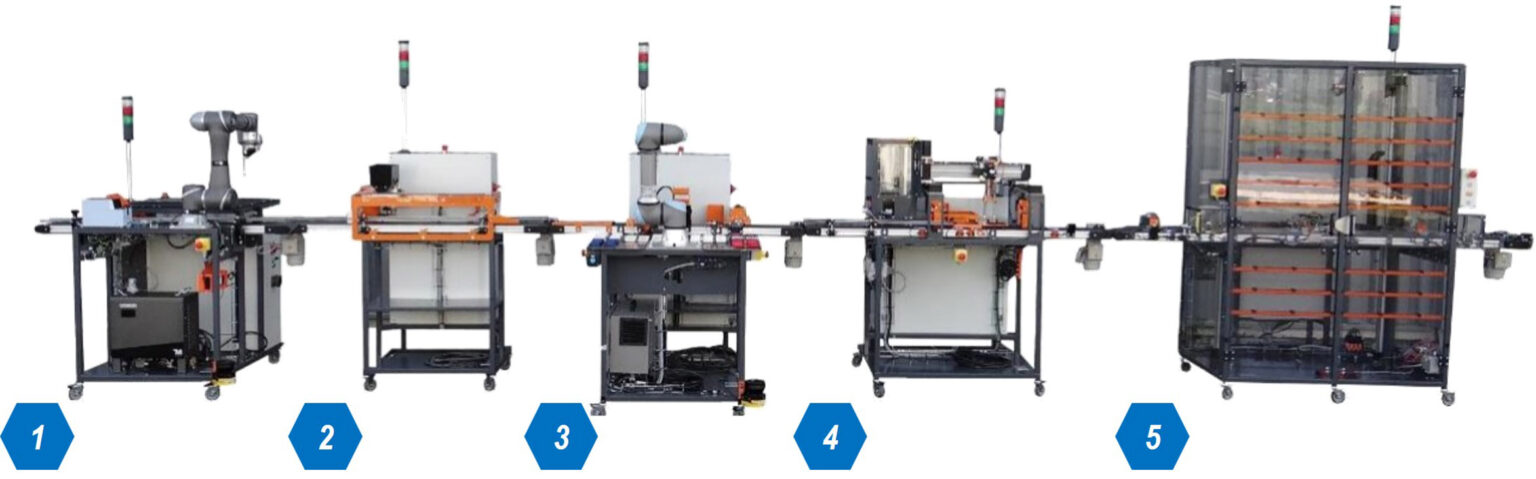

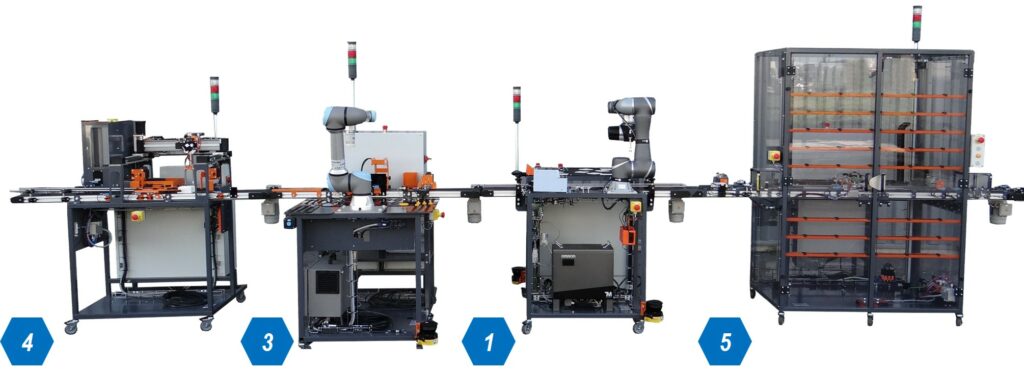

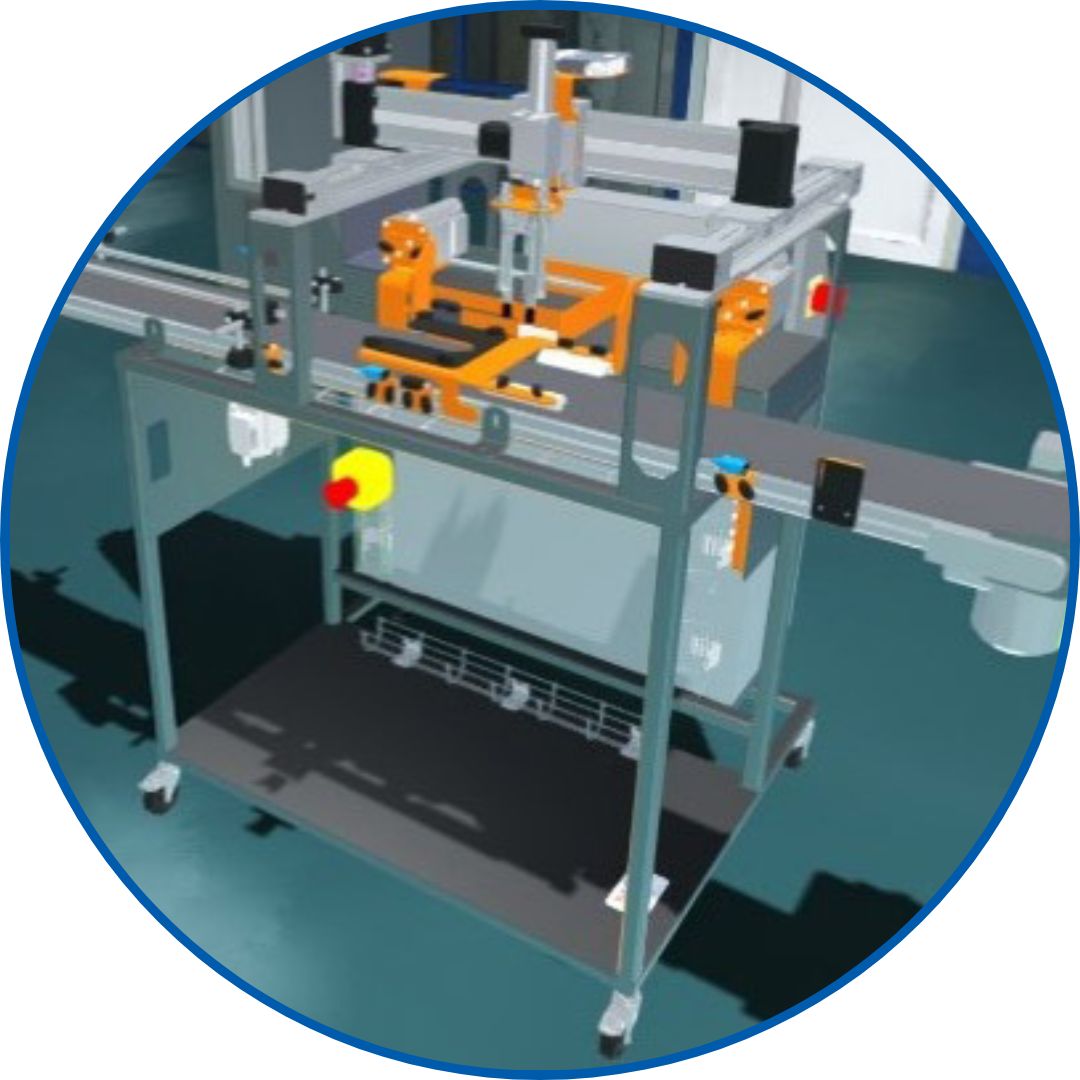

ErmaSmart is a didactic production line composed of autonomous and modular workstations that can be operated separately. Each user is free to compose its own line according to its needs and budget. ErmaSmart is easily moveable. ErmaSmart allows to cover both the teaching of production management, industrial maintenance and automation/robotics.

"Industry 4.0" themes covered

Technical solutions

🔸Siemens PLCs, HMI & supervision (Schneider on request)

🔹Visual instructions & MES Tulip

🔸IO-Link smart sensors & Industrial IoT Sick gateway

🔹AGV MiR100 mobile robot or Puddu Kettybot

🔸Universal Robots, Dobot, Omron and Franka Collaborative robot

🔹2D and 3D Cartesian robots

🔸 Dynamic and energetic management of conveyors

🔹 Sick laser scanners & light curtains

🔸Diota, Hololens & Epson/Brochesia augmented reality

🔹 3D Virtual Universe Pro digital twin

Key points

Quick preparation

Easy to prepare activities thanks to instant start-up instant start-up

Easy to clean

Operates with recyclable consumables and does not require cleaning before and after use

Two process

Use in “Packaging” mode (granules) or in “Assembly” mode (reduction gear)

Robust solution

Reliable systems (welded frames and industrial components) allowing many assemblies, disassemblies and format changes

Evolving line

Evolving line (integration of peripheral systems and components) and consumables (dimensions of jars, bottles, etc.) according to budgets

Teaching activities

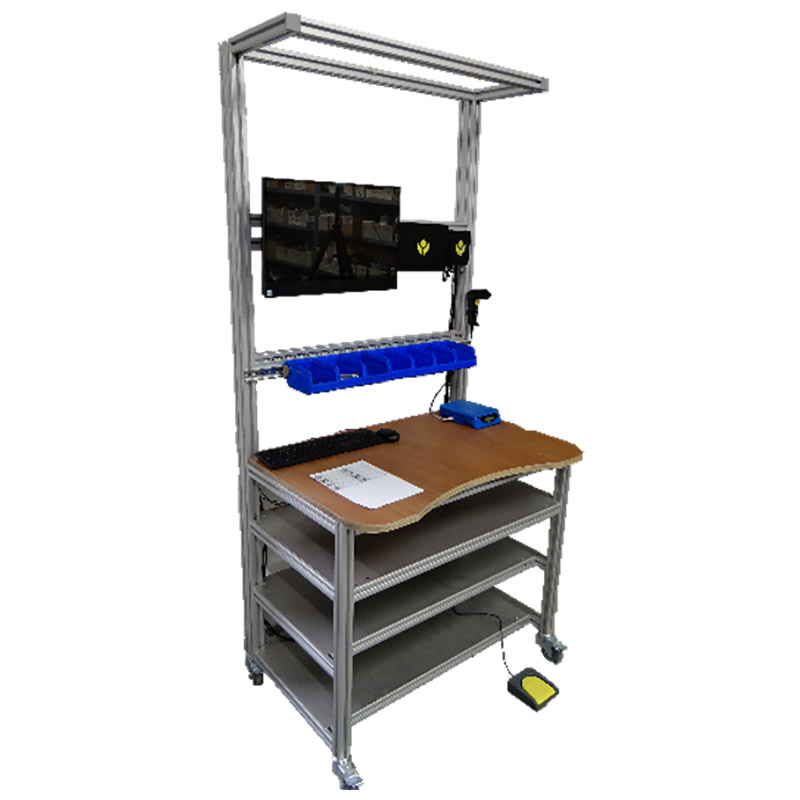

• Production

• Line operation

• Line reconditioning following a change

in production format

• Supervision on Ethernet network)

• Action and acquisition chains

• Regulation and control

• Diagnosis

• Prevention

• Improvements

• Assembly and disassembly

• Adjustments

• Wiring and connection

• Scheduling

• Control charts

• Lean SixSigma

• Automation

• Robotics

• 3D constructive solutions

• Workstation extensions

Our partners and suppliers

Video

Gallery of our ErmaSmart lines

ErmaSmart in Packaging Mode

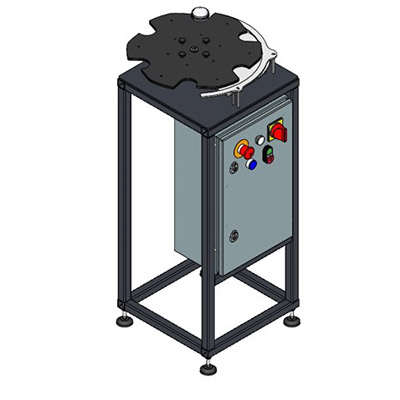

2D jars/bottles unscrewing

Broadcast granule dosing

Stoppering of jars/flasks and personalisation with over-stoppers

Putting jars/flasks in trays

Production storage and automatic order picking

ErmaSmart in Assembly Mode

Placement of box/pallet on conveyor and placement of gearbox base in box/pallet

Assembly of the input shaft, the three “planets”, the central gear with output shaft on the gearbox base

Assembling and screwing the gearbox top cover

Production storage and automatic order picking

2D jars/bottles unscrewing

Broadcast granule dosing

Stoppering of jars/flasks and personalisation with over-stoppers

Putting jars/flasks in trays

Production storage and automatic order picking

Placement of box/pallet on conveyor and placement of gearbox base in box/pallet

Assembly of the input shaft, the three “planets”, the central gear with output shaft on the gearbox base

Assembling and screwing the gearbox top cover

Production storage and automatic order picking