Regulflex

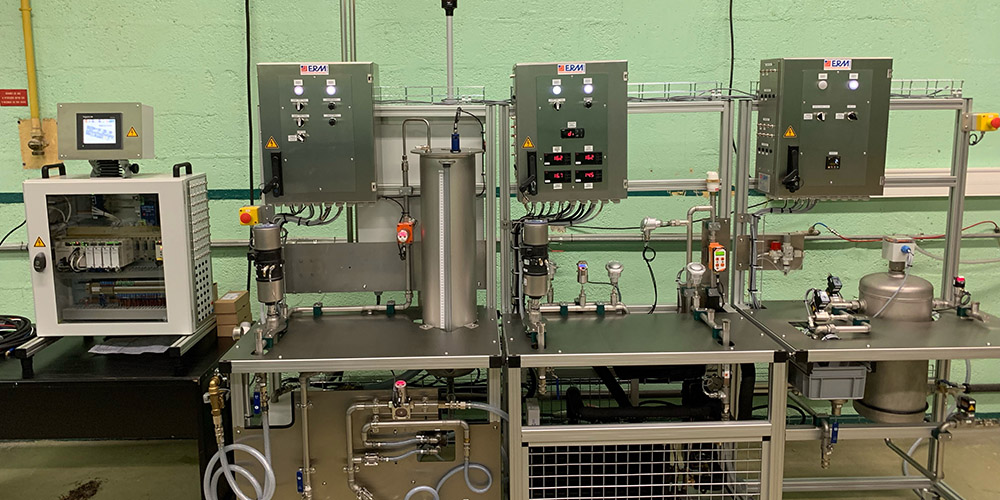

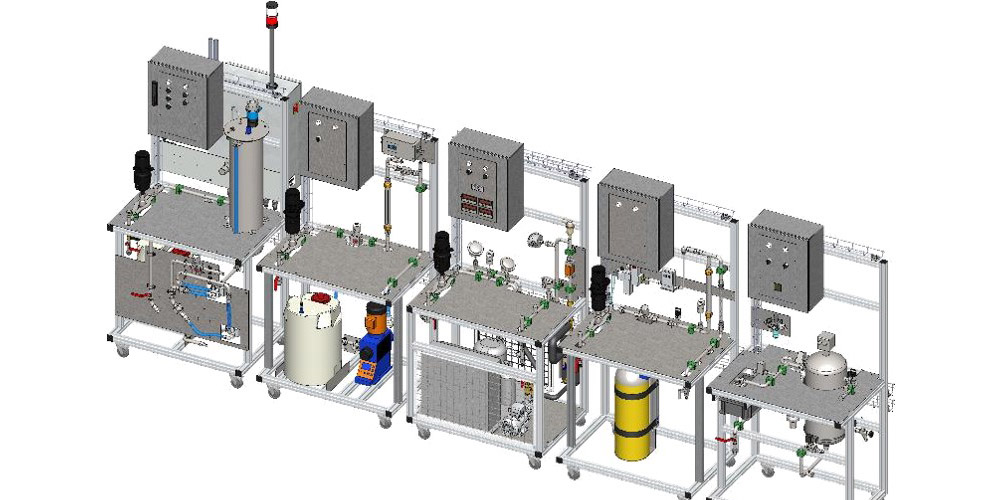

Modular didactic line for the production of carbonated drinks, to study process control

Presentation

Regulflex is a modular didactic line for the production of carbonated drinks, to study process control. This revolutionary approach to teaching process control is based on the use of a real process – the manufacture of carbonated soft drinks – to put the theoretical knowledge acquired into practice. Students are required to work on different stages of the manufacturing process, enabling them to grasp each aspect individually and as a whole. Thanks to the modularity of the systems, each module can operate independently or be interconnected with the other modules, reproducing a real production environment (process mode).

These modular systems offer the possibility of implementing different types of control, from simple On/Off (ON/OFF) control with or without hysteresis and using P, PI, PID algorithms, to more complex control such as Split Range, Mixed, Cascade, Proportional, Adaptive, and many others. Physical quantities such as level, flow, pressure, temperature and other associated parameters are included.

Key points

Robust solution

Robust operating parts incorporating industrial components (stainless steel piping)

Modularity of the controllers

Modularity of the controllers (3 different types of controllers: industrial process controller, PLC and Digital Control System DCS)

Large work surface

Up to 12 students can work simultaneously

Operational modularity

Modularity of the operating parts: one system is sufficient to start work, and various systems can be assembled to suit different study contexts (cold water production, dosing, carbonation and pressurised storage).

Manufacturing process

The manufacturing process has a number of advantages, including a playful approach and the presence of the main physical quantities, such as level and flow. It is also easy to use and contextualise, for example in water and air. Finally, there are simple controls (TOR, P, PI, PID, etc.) and complex controls (cascade, ratio, split range, etc.).

Technical solutions

🔹Level measurement (ultrasonic, capacitive, hydrostatic)

🔸Flow measurements (vane, vortex, rotameter, ultrasonic, thermal mass)

🔹Pressure measurements (relative, differential)

🔸Temperature measurements (PT100, PT1000, thermocouple J, thermocouple K, displays/transmitters)

🔹Valves (with analog positioner, solenoid valve, thermal mass flow controller for air/CO2)

🔸Pumps (volumetric dosing, volumetric rotary vane)

🔹Converters (frequency, current-to-current, current-to-voltage)

🔸Storage (atmospheric and pressurized stainless steel tanks)

🔹Processing components (plate heat exchanger, static mixer)

🔸Industrial refrigeration (condensing unit, pressure reducer, filter drier, control valve, thermostats)

🔹Communication & Fieldbus (Ethernet, Io-Link, Hart)

🔸Process control (controller, PLC, DCS)

🔹Calibration tools (calibrators (mA / mV / Thermocouple / RTD), decade resistor box, precision

manometer with pump)

🔸Other measurements (Brix degree, density)

Our partners and suppliers

Teaching activities

• Signal conditioning

• Measuring the controlled variable

• Transmitting information

•Identifying a stable / integrating system in OL / CL,

•Acting on a valve according to the direction /

CV / characteristics)

• Production

• Process control

• Monitoring

• Alarm management

• Supervision on the Ethernet

network